Restoration of the Witches’ Sabbath panel

This month, we take a closer look at the restoration of an intriguing work of art: The Witches’ Sabbath, a 16th-century masterpiece by Frans Verbeek. We focus on the restoration of the oak support, carried out by Brian Richardson, a specialist in the conservation and restoration of wooden objects and furniture.

Structure and damage pattern of the wooden carrier

The panel consists of three horizontally oriented oak boards, the top one being 26.5 cm wide, the middle one 21.0 cm, and the bottom one 23.0 cm. This is not clearly visible on the back; during previous restorations, the glue joints were covered with veneer, which made the situation very confusing. It is notable, however, that the panel is only 7 mm thick, which is thin for a panel of this size.

An earlier restoration treatment, presumably from the second half of the last century, included the addition of a support structure at the back to reinforce the panel. Despite the attempt to develop a sprung support structure, the system falls short because the window construction is immobile. Saw marks and serrations in the wood suggest that the panel was thinned, possibly long before the 20th-century support structure. The patina on the backside has been partially removed for the support construction, and the cracks and glue seam have been reinforced with V-shaped inserts in walnut, but not all glueing is even, causing level differences at the front.

Removal of support structure

To improve the condition of the panel, Brian first loosened the support structure, including the screws on the back. He cut away the fastening blocks one by one with a gouge and chisel and finely sanded the panel to smooth the glue residue. The remnants of synthetic glue in the wood structure itself were not removed.

Correction of level difference

After removing the support structure, Brian decided to remove the V-shaped inserts – where the level difference to a crack was most disturbing – to open up the crack and improve the level difference. The expectation was that the V-shaped inserts would follow the cracks nicely. Once the inset pieces of wood were removed, only 2-3 mm would then remain where the crack would need to be loosened. Compresses were used to soak off the glue to then open the crack. Next, Brian carefully cut away the V-shaped inserts on the back with different types of wood chisels. Finally, the white glue, with which the inserts had been glued, was soaked loose with acetone and removed so that the notches were completely clean.

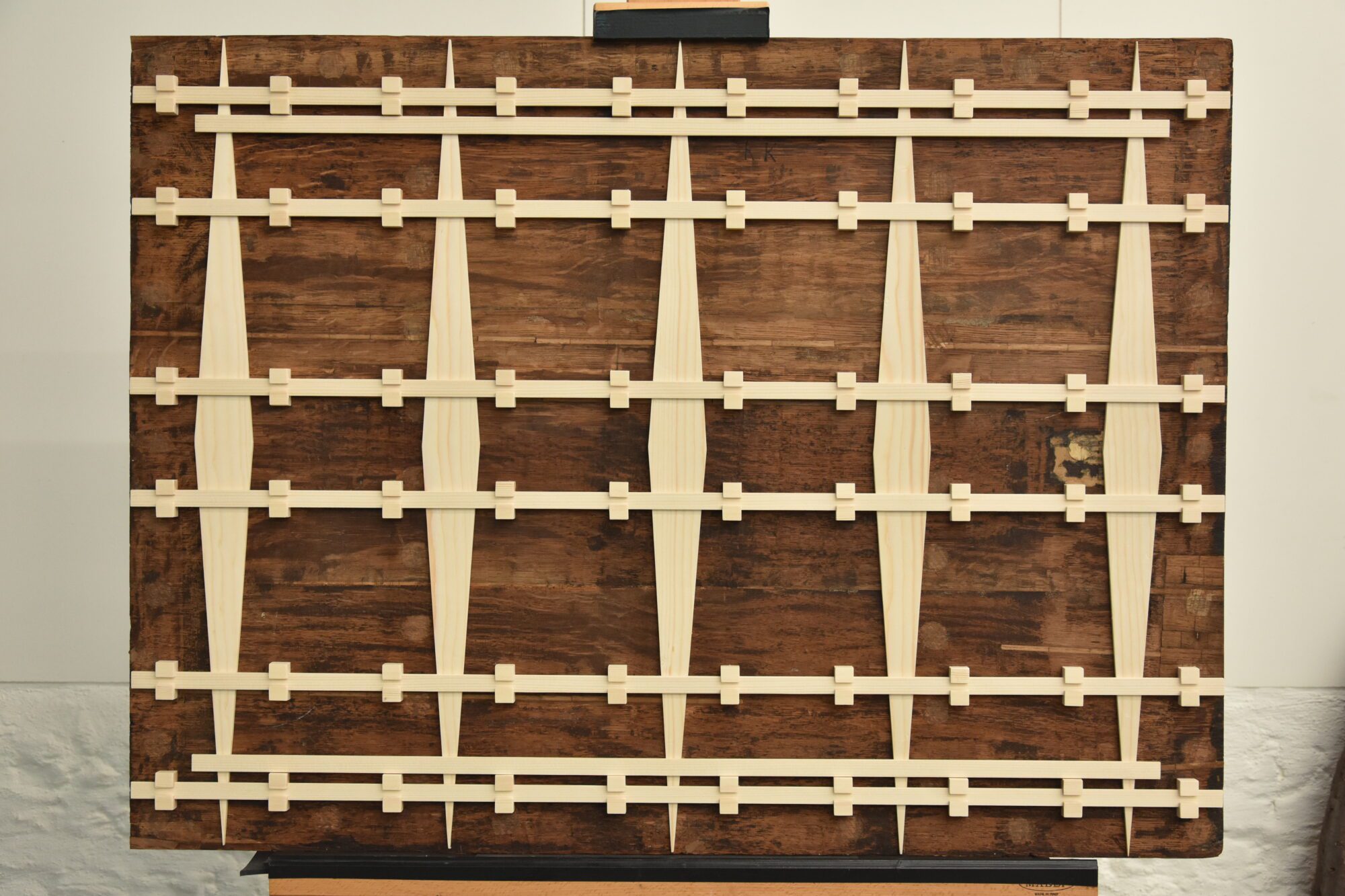

New construction

Without support, the panel was too fragile, so Brian placed a new support structure on the back. This system consisted of slats that were glued to the back with fish glue using small blocks. Each slat was slid into grooves in the blocks, creating an equal distribution of pressure across the backside. After this addition, the panel became considerably more stable and again manipulable.